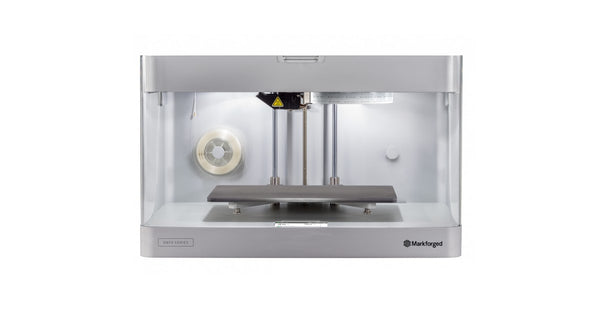

Markforged Onyx Pro (Gen 2) desktop 3D printer

SKU: MARKF-FPR4012

Regular price

$9,600.00

Shipping calculated at checkout

Forge parts in your office - printed parts on every engineer's desk.

The Onyx Pro is an advanced professional 3D printer – built around the Continuous Fiber Reinforcement (CFR) process to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Onyx Pro to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

In addition to more common FFF features, the Onyx has a 2nd-generation fiber reinforcement system that enables you to lay down continuous fiberglass into parts. Only Markforged composite printers are capable of printing continuous fiber reinforced parts, which can replace machined aluminum parts.

Markforged's Onyx 3D printers are designed to give every engineer access to strong Onyx or fiberglass parts. Every part of Markforged's digital forge - whether hardware, software, or the material - provides a reliable, unique 3D printing experience. Let the Onyx series inspire you.

Onyx is a 3D printing material with integrated chopped carbon fiber. Many engineers start with an Onyx One printer and use this material to create parts for a wide range of applications. However, as your needs may change, it is possible to upgrade your machine to the Onyx Pro and also work with fiberglass as a composite material.

Printing with Onyx

Because Onyx is made of nylon and contains shredded carbon fibers, it is very robust. For this reason, it achieves 3.5 times the stability of nylon. It also has an excellent surface quality. You can also print with Markforged Smooth TPU 95A, which is a rubber-like material that gives you the ability to create flexible, shock absorbing parts (Thermoplastic Polyurethane). Another material of choice for prototyping and validation is Markforged Precise PLA - a cost effective way to make sure your design is on point.

One key application of parts printed in Onyx is work holding equipment.

Markforged Onyx material compared to ABS:

- 240% stronger

- 50% more heat resistant

- 25% stiffer

The Onyx Pro, with a second print nozzle exclusively for continuous filament fiberglass, prints astonishingly strong parts with an excellent weight to strength ratio. That's why it's popular with our industrial customers as an entry-level machine for making really strong fiberglass-reinforced parts.

Build volume and layer height:

- 320mm width

- 152mm depth

- 154 mm height

- 100 μm layer height

Exceptionally strong 3D printed parts for industrial use require innovative and intelligent software. For this reason, Eiger, Markforged's proprietary slicing software is easy to use and allows you to easily control the stability and quality of your prints. With a cloud version included with every machine, Eiger gives you the benefits of automatically improving functionality through seamless updates.